Single-Piece Semi Automatic Box Stitcher, Stitching, Stapling Machine

CorroGo #:EID2A Mfr # :X1-2800

- Double servo control and high speed

- Lead time around 15 business days

We offer a full line of semi automatic stitchers and fully automatic stitchers which can be custom tailored to your exact production demanding.

Features & Advantages:

- Designed for single piece box, with and/or without boxcovers (optional for without-covers), 3-ply/5-ply, or 5-ply/7-ply boards (optional for 7-ply)

- Order and box size changes are easily and quickly performed

- Easy and safe operator and maintenance

- User friendly touch screen operator interface enhances control

- Single nail, double nail, and strengthen nail are one-touch-change

- Automatic counting at the feeding and the finished boxes conveying to strapping in stacks

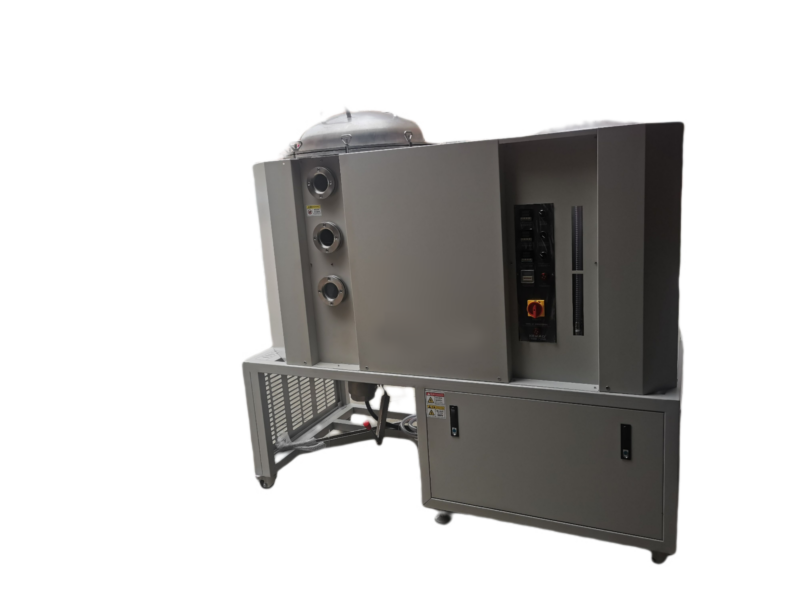

- Adopts servo control system

- Stitching spacing can be well pre-set via touch screen up to 140mm

- Automatically adjusts boards thickness with quick change in single/double walls

- Automatically adjusts the first stitch and screw

- Feeding speed is adjustable to fit operator handling

- Auto monitoring on stuck nail and improper operation

- Main spare parts used: Yaskawa, Omron, Siemens, Schneider, AirTac etc.

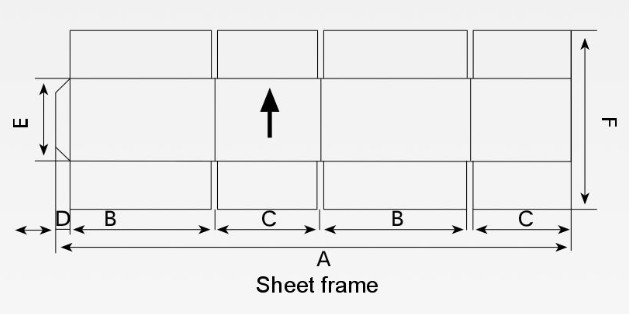

Technical Parameters:

| Mechanical Speed | 500 stitches/min |

| Stitching spacing (D) | 30-140mm |

| Number of stitching | 1-99 stitches |

| Boards thickness applied | 3-10mm |

| Stitching wire | 17# (2.0 x 1.0mm), 18# (1.8 x 0.8mm) |

| Max. board size (B+C) x 2 | 2800mm |

| Min. board size (B+C) x 2 | 606mm |

| Max. board width (F) | 1515mm |

| Min. board width (F) | 300mm |

| Cover sizes (C) | 125-500mm |

| Stitching overlap (D) | 30-50mm |

| The 1st stitch | 20-380mm |

| Machine dimensions | 2800 x 2600mm |

| Machine weight | 2000Kg |

| Feeding table height | 900mm |

| Nailing types | Single / / /, Double / / /, Mix / // / |

| CorroGo # | EID2A |

|---|---|

| Mfr# | X1-1800 |

| Origin | China |

| Electricity | 380V 3-Phase, 50Hz, or custom |

| General Power | 5 KW |

Related products

This product has multiple variants. The options may be chosen on the product page

This product has multiple variants. The options may be chosen on the product page

This product has multiple variants. The options may be chosen on the product page