Corrugator Belt Guide, Aligner, Alignment

CorroGo #: PDC1A Mfr #: TDSC-X1

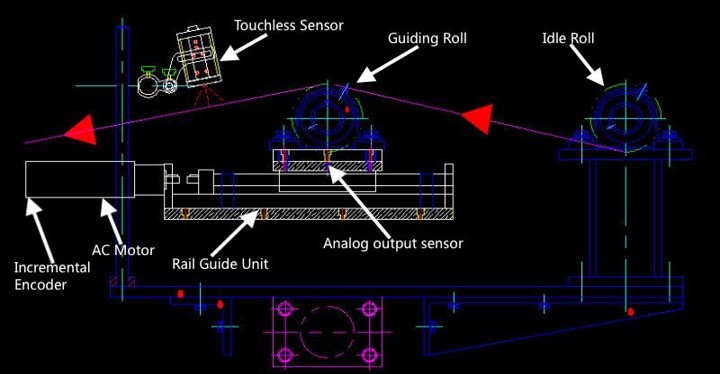

- Advanced design with touchless sensor

- Instock item ships in 5 business days

Features & Advantages of TDSC-X1 Corrugator Belt Guide

- Detecting the belt tracking by touchless infrared sensor avoids abrasion problem with the conventional detecting plate, and 0.1mm accuracy of detector is achieved.

- Drive unit has highly precision close-loop incrementally encoded servo motor and analog output sensor that avoids damages to the belt due to S shape tracking guided.

- Digital operation and control system ensures higher reliability, higher control accuracy and better user friendly.

- Achievements of longer belt life, less slitting boards edges and better boards quality.

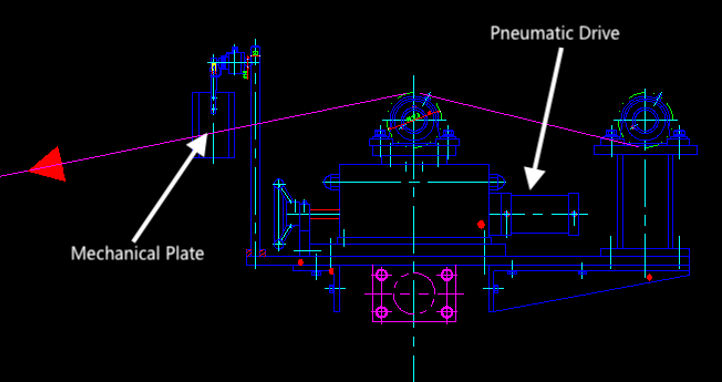

Installation (drawings affixed next page) :

- New TDSC-X1 Guide must be kept the same level of height as the previous guide.

- Keep both operation and drive side being at the same level of height.

- Both centers of guiding roll and rail guide must be at the same level.

|

Infrared Touchless Detector: |

The device sends infrared bands to the material, and reflection goes to CCD receiver module, in this way the edge position of web is detected dynamically.

|

|

|

Control Panel – Digital Control System: |

Receive signal and control the motor motions.

|

|

|

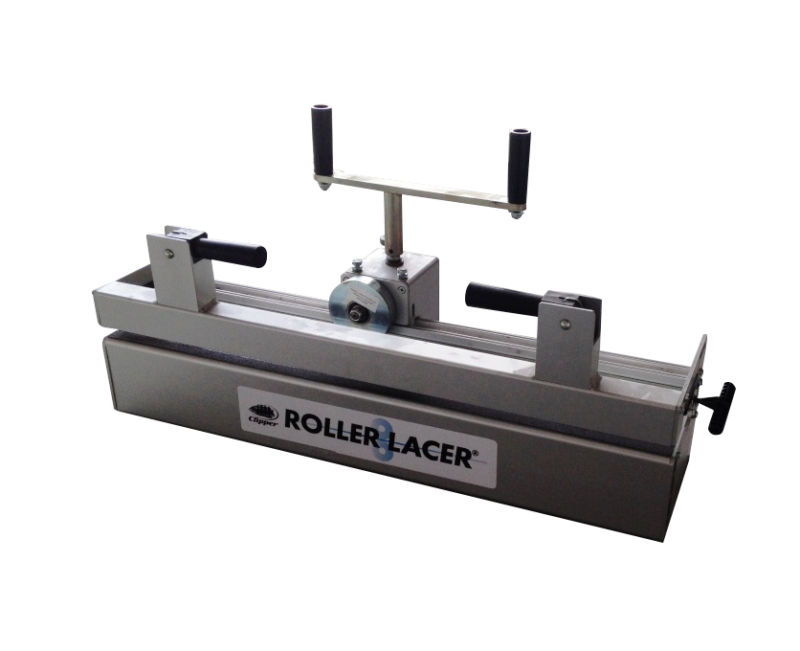

Driver AG2591 |

Features

|

|

|

Inductive analog output sensor

|

| Inductive analog output sensor—Detects position of the target metal object within specific distance, and then sends out analog signal accordingly. | |

| B+F sensors detecting ranges from 2—5mm, 3—8mm, and 15—40mm. It’s reliable and precision even under rigid conditions due to low rate of temperature drift. |

| Conventional Belt Guide Installation: | Our New & Advanced Belt Guide Installation: |

|

|

| Installations – TDSC-X1 | |

|

|

|

|

| CorroGo # | PDC1A |

|---|---|

| Mfr # | TDSC-X1 |

| Country Of Origin (subject To Change) | China |

| Corrugator Width | Fit All Widths |

| Drive Roller | Excluded |

| Detecting Accuracy | ±0.1mm |

| Control System | Close Loop |

Related products

This product has multiple variants. The options may be chosen on the product page

Select options

This product has multiple variants. The options may be chosen on the product page

This product has multiple variants. The options may be chosen on the product page

SALE

Select options

This product has multiple variants. The options may be chosen on the product page

Select options

This product has multiple variants. The options may be chosen on the product page

This product has multiple variants. The options may be chosen on the product page